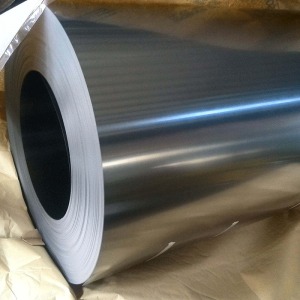

Cold Rolled Steel coil

PRODUCT INTRODUCTION

This produces steel with precision dimensional tolerances and a wide range of controlled surface finishes. Use Cold-rolled steel where thickness tolerance, surface condition, and uniform mechanical properties are of the utmost importance.

We offer a wide range of cold rolled specialty alloy, high carbon, low carbon, and high strength low alloy (HSLA) precision tolerance strip steel.

COLD ROLLED STEEL COIL IN VARIOUS SIZES:

We can slit coil to the following specifications:

- Thickness: .015mm - .25mm

- Width: 10mm - 1500mm

- ID:508 mm Or your requirements

- OD610 mm Or your requirements

- Weight of coil – 0.003-25 tonnes Or your requirements

- Weight of sheet bundles – 0.003-25 tonnes Or your requirements

Capabilities vary based upon grade and thickness. Please inquire for specifics or requirements outside of the above ranges.

DIFFERENCES BETWEEN HOT AND COLD ROLLED STEEL:

The main difference between hot and cold rolled steel is in how they are processed. Hot rolled steel is steel that has been rolled at high temperatures, while cold rolled steel is essentially hot rolled steel that is further processed in cold reduction materials. Here, the material is cooled followed by annealing and/or tempers rolling. Steels of different grades and specifications can be either hot or cold rolled.

Applications:

Cold rolled steel sheet and coil is commonly used for applications in which dimensional tolerances, strength and surface finish quality are critical. Applications that use cold rolled steel products include:

Metal Furniture、Automobile Components、Electronics Hardware、Home Appliances and Components、Lighting Fixtures、Construction.

PACKAGING&LOADING:

3 layers of packing, inside is kraft paper, water plastic film is in the middle and ouside steel sheet to be covered by steel strips with lock, with inner coil sleeve.