NEW YORK, Nov. 23, 2022 /PRNewswire/ — The structural steel market is expected to grow at a CAGR of 6.41% during 2022-2027.

MARKET INSIGHTS

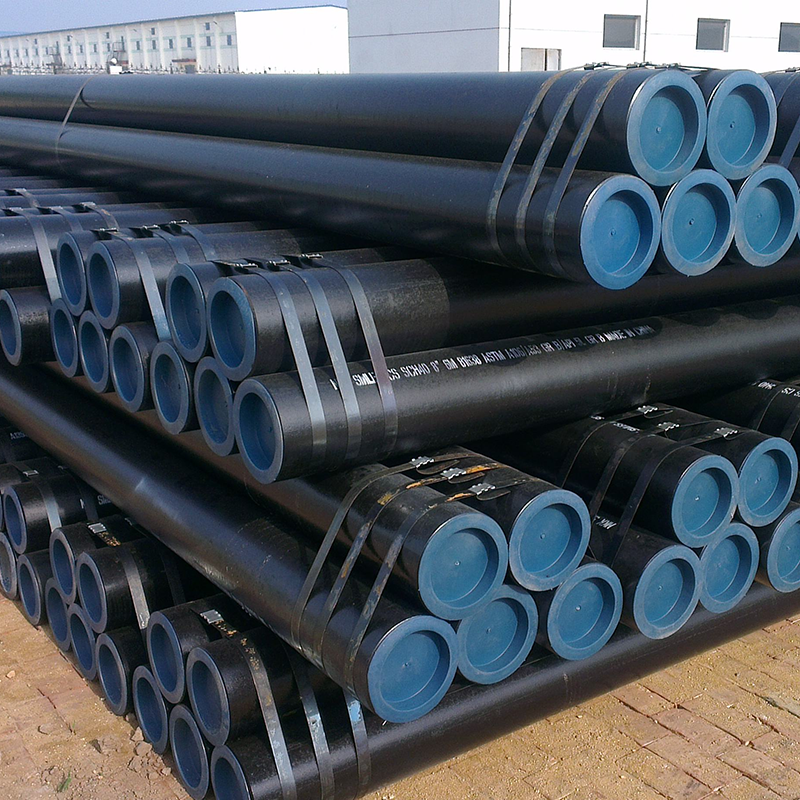

Structural steel is carbon steel, meaning carbon content is up to 2.1% by weight. Therefore, we can say that coal is the essential raw material for structural steel after iron ore. Many times, structural steel is used in various construction activities. Structural steel comes in numerous shapes, giving architects and civil engineers freedom in designing. Structural steel is used to construct warehouses, aircraft hangers, stadiums, steel and glass buildings, industrial sheds, and bridges. In addition, structural steel is wholly or partially used to construct residential and commercial buildings. Structural steel is an adaptable and convenient construction material that helps in manufacturing versatility and provides structural strength without excessive weight, from commercial to residential to road infrastructure.

Structural steel is also used in various industries such as power generation, electricity transmission & distribution, mining, etc. Most of the substructure components in the mines are supported by structural steel beams and columns. Structural steel is used to construct all workshops, offices, and mine structural sections such as mining screens, fluidized bed boilers, and structures. Structural steels are often specified by industry or national standards such as the American Society for Testing and Materials (ASTM), British Standards Institution (BSI), International Standards Organisation (ISO), and so on. In most situations, standards specify fundamental requirements, such as chemical composition, tensile strength, and load-carrying capacity.

Many standards across the world specify structural steel forms. In brief, standards specify angles, tolerances, dimensions, and cross-sectional measurements of steel called structural steel. Many sections are manufactured by hot or cold rolling, while others are formed by welding flat or curved plates together. The structural steel beams and columns are connected by using welding or bolts. Steel structures are widely used in the construction of industrial sheds due to their ability to withstand enormous loads and vibrations.

Additionally, ships, submarines, supertankers, ladders, steel floors and grating, steps, and manufactured steel pieces are examples of maritime vehicles that use structural steel. Structural steel can withstand external pressures and is quickly produced. These characteristics make structural steel suitable for use in the naval industry. Therefore, many structures that support the marine industry, such as docs and ports, use a wide range of steel structures.

MARKET TRENDS & OPPORTUNITIES

Growing Market of Light Gauge Steel Framing

Light gauge steel frame (LGSF) structure is a new-generation construction technology widely used in residential and commercial construction in the structural steel market. This technology uses cold-formed steel. Generally, a light gauge steel frame is applied for roof systems, wall systems, roof panels, floor systems, decks, and the entire building. Designing LGSF structures offers great flexibility in the design. Compared to conventional RCC and wooden structures, the LGSF can be used for long distances, providing flexibility in design. Using steel in construction permits designers and architects to design freely by taking advantage of the high strength of steel. This flexibility of LGSF offers a large floor area compared to RCC structures. The LGSF technology is cost-effective for constructing residential and commercial buildings; therefore, the demand for LGSF structures is expected to grow in emerging economies due to the low disposable income of people.

Growing Demand for Sustainable Construction Materials

The demand for sustainable construction materials is increasing rapidly in the global structural steel market as these materials are environmentally friendly and help the construction industry to practice sustainable development. Structural steel is one of the sustainable construction materials for the construction industry that has been used in many buildings and industrial shed projects. Structural steel is widely used in industrial sheds; structural steel components get damaged because of continuous wear and tear due to various manufacturing activities. Therefore, structural steel components are regularly replaced and repaired to maintain structural integrity. Structural steel is a highly recyclable construction material that is generally used in industrial sheds and some residential structures. Additionally, structural steel buildings’™ life is more than regular bricks and concrete structures. Steel structures take less time to construct, and the wastage of materials is less due to the pre-engineered nature of construction.

INDUSTRY CHALLENGES

Expensive Maintenance

The maintenance cost of structural steel buildings is higher than conventional buildings. For example, if the steel column gets damaged, you need to replace the whole column, but for conventional columns, there are some procedures to repair that damage. Similarly, steel structures need anti-rusting coating and paint more often to prevent steel structures rust. These anti-rust coats and paints increase the maintenance cost for steel structures; thereby, the expensive maintenance causes a hindrance to the growth of the structural steel market.

The structural steel market(Steel pipe,Steel bar,Steel sheet) is expected to grow at a CAGR of 6.41% during 2022-2027

Post time: Nov-24-2022